A pressure transducer is a device that converts pressure into an electrical signal. It is also known as a pressure sensor or pressure transmitter. The device measures the pressure of gas or liquid and converts it into an electrical signal that can be read by a computer, monitor, or other device. The signal can then be used to display the pressure on a gauge or to control various processes in industrial or mechanical applications. Pressure transducers are commonly used in industries such as automotive, medical, off-road equipment, and automation.

Sensing element

This is part of the transducer that comes into contact with the substance being measured and translates the physical pressure into a mechanical or electrical signal.

Diaphragm

A flexible membrane that is commonly used as the sensing element. The diaphragm will deform in response to changes in pressure, which is then translated into an electrical signal.

Strain gauge

A type of sensing element that uses a wire or foil that changes resistance in response to mechanical stress. Strain gauges are often used with a diaphragm to measure pressure.

Amplifier

The electrical signal generated by the sensing element is typically very small and needs to be amplified by the transducer’s electronics to produce a usable output signal.

Output signal

The final output signal can take many forms, such as a voltage, current, or frequency, depending on the transducer’s design and intended application.

Pressure transducers can be categorized into two main types based on their technology: strain gauge-based pressure transducers and capacitive pressure transducers. Both types of pressure transducers feature a wide range of advantages, depending on the intended application.

Strain gauge pressure transducers are devices used to measure the pressure of fluids and gases. They work by converting the applied pressure into a strain on a diaphragm which is measured by a strain gauge attached to the diaphragm.

The strain gauge measures the change in resistance caused by the strain on the diaphragm, which provides an accurate measure of the pressure being applied. The output signal from the strain gauge is amplified and converted into a voltage or current signal that can be read by a pressure indicator or controller. Strain gauge pressure transducers are commonly used in quasi-static applications such as pressure monitoring of a process or instrumentation.

Capacitive pressure transducers are devices that convert pressure into an electrical signal by measuring changes in capacitance. They typically consist of a sensing element and a reference element separated by a diaphragm. When pressure is applied to the diaphragm, it causes a deflection that changes the distance between the sensing and reference elements, which in turn changes the capacitance. This change in capacitance is then converted into an electrical signal and transmitted to a data acquisition system for processing and analysis.

Capacitive pressure transducers are commonly used in industrial, automotive, aerospace, and medical applications, where accurate and reliable pressure measurement is essential. They offer high accuracy, stability, and linearity, and can operate over a wide range of pressures and temperatures. They are also typically small, lightweight, and durable, making them ideal for use in harsh environments.

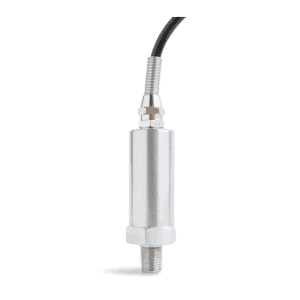

Compact Pressure Transducer

Digital Mobile Pressure Transducer

Industrial Vacuum / Pressure Transducer

High Pressure Transducer

Construction and civil engineering: Pressure transducers are used in construction and civil engineering applications to monitor the pressure in concrete during construction and to measure soil pressure in earth retaining structures.

Agriculture and irrigation systems: Pressure transducers are used in irrigation systems to measure and control water pressure for efficient and effective watering of crops

Medical and healthcare equipment: Pressure transducers are used in medical equipment such as ventilators and blood pressure monitors to measure and control pressure in critical applications.

Environmental monitoring: Pressure transducers are used in environmental monitoring applications to measure atmospheric and water pressure, and to monitor pressure changes in oceans, lakes, and rivers.

Energy production and transmission: Pressure transducers play a critical role in the oil and gas industry by monitoring the pressure in pipelines and other equipment to ensure safe and efficient production and transmission.Industrial manufacturing processes: Pressure transducers are commonly used to measure fluid pressure in manufacturing processes including semiconductor fabrication, food and beverage production, and chemical manufacturing.

HVAC systems: Pressure transducers are used to monitor and control air and fluid pressure in heating, ventilation, and air conditioning (HVAC) systems to ensure efficient and effective operation.

Automotive and aerospace industries: Pressure transducers are used in almost all types of vehicles and aircraft to monitor tire pressure, fuel pressure, engine oil pressure, and hydraulic system pressure.

Pressure transducers work by converting pressure measurements into electrical signals that can be read and interpreted by various devices. The transducer typically consists of a sensing element, which is exposed to the pressure being measured, and an electronic circuit that translates the changes in pressure into a corresponding voltage signal.

The sensing element can be made of various materials, but commonly uses a thin metal diaphragm that flexes or deforms in response to changes in pressure. This mechanical deformation generates an electrical signal, which is then amplified and converted into a numerical value by the associated electronic circuitry.

Some pressure transducers also incorporate additional features, such as temperature compensation or signal conditioning, to ensure accurate and reliable measurements. The resulting output signal is typically calibrated to correspond with specific pressure levels or units of measure, enabling users to accurately monitor and control pressure-related processes.

1. What is the accuracy of pressure transducers?

The accuracy of pressure transducers can vary depending on the manufacturer and model. High-quality transducers can have accuracies of +/-0.05% of full scale, while lower-cost transducers may have accuracies of +/-1% or more.

2. What is the maximum pressure range of pressure transducers?

The maximum pressure range of pressure transducers can vary depending on the manufacturer and model. Some transducers can measure pressures as low as a few millibars, while others can measure pressures up to tens of thousands of psi.

3. Can pressure transducers measure vacuum?

Yes, pressure transducers can be used to measure a vacuum where the output can either increase with increasing pressure or decrease. However, the transducer’s range and measurement accuracy may be different for vacuum measurements compared to positive pressure measurements.

4. How do I select the right pressure transducer for my application?

When selecting a pressure transducer, consider factors such as the pressure range, accuracy, output signal, environmental conditions, and temperature.

We hope this article has helped you understand what are Pressure Transducers, Their Applications, and How They Work.

Thank you for the information. One of our representatives will get in touch with you shortly.